Introducing the International S13 Powertrain & Engine

The S13 Integrated Powertrain features a clean sheet design with the engine, transmission and aftertreatment developed and integrated concurrently, ensuring maximum efficiency without compromising performance. In comparison to the first-generation International® A26 engine specified with the 12-speed overdrive Eaton Endurant HD automated transmission, the S13 Integrated Powertrain is the lightest weight powertrain on the market. The S13 Integrated offers up to a 15% gain in fuel efficiency. It also provides improved reliability and sustainability, marking a leap in the progress toward carbon-neutral transport.

Key Features of the S13/T14 Powertrain

- Engineered from the ground up in collaboration with Scania

- Reduced components and complexity providing increased reliability

- Designed with no EGR cooler required

- Industry-leading fuel economy. See our own fuel economy test report here.

Engine Design

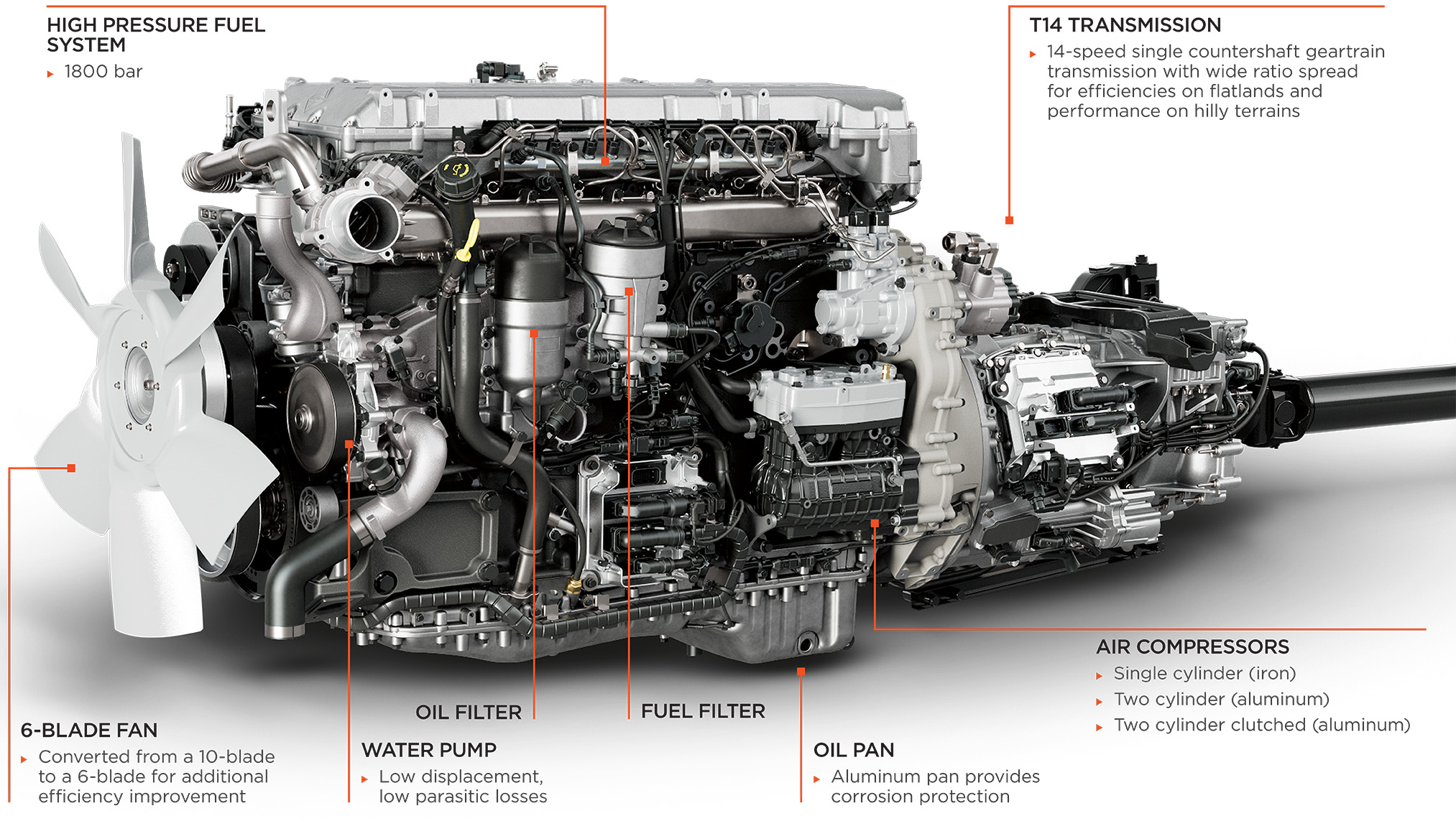

The 13-liter International S13 engine achieves advanced fuel efficiency and performance through combustion efficiency and a reduction of friction and pumping losses.

The S13 engine operates on low revolutions and higher torque equating to fewer fuel injections and less fuel consumption. Designed with selective catalytic reduction (SCR) technology as the primary emissions reduction technology in mind, the S13 engine has no exhaust gas recirculation (EGR) cooler and flows 100% of the exhaust to the turbocharger in normal engine operating conditions. This process delivers more power and improved engine performance. Eliminating the recirculation of exhaust gas ensures a more complete fuel burn and allows cleaner air to enter the combustion chamber on the intake cycle to mitigate soot buildup.

With the goal of improving uptime through elimination of subcomponents, the S13 engine has succeeded in improving efficiencies in multiple areas. A fixed geometry turbocharger reduces system complexity and increases reliability. Low friction materials and finishes are used for the liners, rings and bearings. The design eliminated the downstream fuel injector and the high-pressure fuel pump operates at a lower pressure of 1,800 bar. Additional features include a dual overhead cam design and cast aluminum cam cover and oil pan, 23:1 compression ratio and a compression release brake for maximum engine braking power. The compacted graphite iron block of the S13 engine combined with a cast aluminum cam cover and oil pan help make this the lightest weight 13L powertrain available in North America.

When it comes to performance, the S13 engine has seven engine rating options, with a maximum 515 horsepower and 1,850 lb-ft of torque at 2,000 revolutions per minute (RPM) governing speed.

Transmission Features

The first commercial transmission offered by International, the International® T14 is a 14-speed fully automated manual transmission with an electronic clutch actuator to deliver faster, smoother shifting.

As part of the clean sheet design, shifting logic and integrated software controls maximize efficiency and performance resulting in gear shifting that is perfectly matched to engine revolutions.

The T14 features a planetary gear set that supports a compact design and optional programmable reverse speeds. This transmission has two crawler gears for improved heavy load startability and low-speed maneuvering. Complete with deep low-end gearing and shifting smoothness, the T14 delivers efficiencies of a direct drive in an overdrive package.

The S13 Integrated Powertrain offers increased power, with the full torque available at 900 RPM to support drivability. Drivers have shift-on-the-fly capabilities with Economy, Performance and Performance+ modes. Also included are intelligent shifting capabilities, like skip shifting and turning radius offsets.

In addition to multiple shifting capabilities, the T14 transmission includes options for low-speed maneuvering, hill hold, and initial vehicle movement modes.

Dual Stage Aftertreatment - Up to a 15% Boost in Efficiency for On-Highway

Because there’s no EGR during regular operation, NOx must be treated a different way. To do this, the engineers developed an all-new Dual Stage Aftertreatment design that injects a first dose of DEF just downstream of the turbo in the evaporator tube and a second dose inside the aftertreatment container. Since a cooled EGR has been eliminated from the combustion chamber, much less soot or particulate matter is generated. This allows for extended service intervals and eliminates the need for active regens. In fact, the cleaner combustion cycle has so much less soot the engineers were able to eliminate the need for a diesel oxidation catalyst (DOC) in the aftertreatment system. Combined, the aftertreatment system provides a simple, reliable solution that’s easily serviceable.

Through exhaustive simulation work, a new cylinder and piston head design with maximum cooling properties was created. This new double overhead cam design directly equates to less fuel being consumed. But that’s not all. Thanks to the new Dual Stage Aftertreatment system, the heavy (40-50 lbs), expensive ($2,500 approx.) and finicky EGR cooler is no longer needed to reduce emissions. Its absence not only contributes to the S13 being the lightest 13-liter diesel engine available in North America, but it also means 100% of the exhaust flow goes through the new simple, more reliable fixed-vane turbo charger for maximum performance and efficiency.